TMC METAL is a Tungsten copper alloy manufacturer. This special material is applied in various industries. Tungsten copper alloy is durable and strong, so it is good to use for various works.

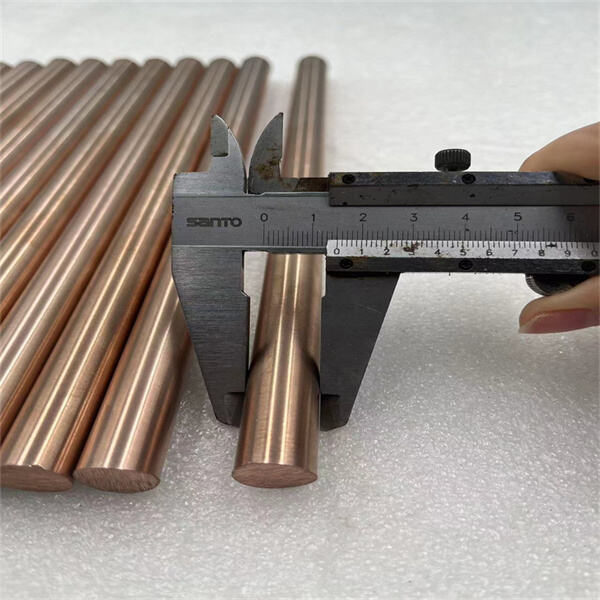

Tungsten copper alloy is a blend of tungsten and copper. This mash-up yields a metal that is superstrong, like tungsten, but also carries currents well, like copper. The candidate material of tungsten copper alloy has good heat resistance and a high melting point. That makes it well-suited to countries with high temperatures.

There are several reasons of using tungsten in various industries. A major reason is strength. It’s stronger than standard copper, so it performs in demanding conditions. Tungsten copper alloy is also a good conductor of electricity and heat, qualities that are crucial for many tasks.

There is a few special things about the Tungsten copper alloy that makes it good to use for industries. An important characteristic is its strength. That means that it can withstand a lot of pressure before breaking. In addition, it conducts heat, making it a good option for hot spaces.

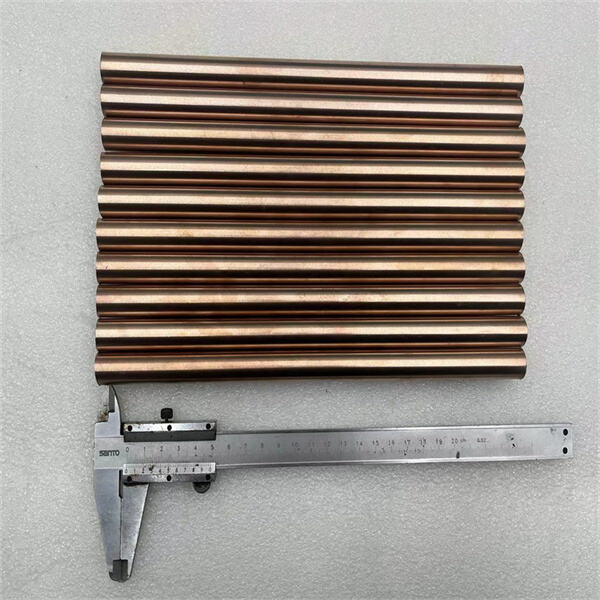

Note TMC METAL does NOT make weak materials that will stand the test of time. Tungsten copper alloy is created to withstand the test of time, and therefore does not need to be replaced frequently. This is good for the channel companies — and it’s also good for the environment. Tungsten copper alloy can also be used harshly, so it can be used in many fields.

Tungsten copper alloy is versatile and can be utilized in various applications. Its strength is very useful across the aviation industry, including in this plane. It is also employed in electronics, as it can conduct electricity and is ideal for use in circuit boards and other components. In medicine, the alloy tungsten copper can often be found in medical devices since it is safe to the body and is strong.

company has 26 years of expertise rare metal and non-ferrous metal processing and production. have cultivated an extensive number of engineers and researchers with professional knowledge to help in the growth of industry. Also, we provide a platform for development of employees. professional staff can provide you with support after sales to address customer concerns provide technical assistance solve any tungsten copper alloy issues that might arise. Make the necessary changes enhance quality the product well as customer service, by gathering and analyzing feedback from customers.

Suzhou Tamuchuan, processing company supplies products located Suzhou with a production facility office space of 2,000 square meters which located in city. main products offer rare metals, ferrous metals as well various other metals. More than 2,000 {{keywords}}' partners cooperate with. experienced R D group available. stable suppliers can assist with large-scale production, high-end production equipment tools. professional quality control team ensures that the product of the highest quality. have good partnership with our suppliers.

company has high-end production equipment processing equipment, can perform high-end, custom metal processing, high-end processing, and difficult processing. We are able to process produce parts metal according customers' specifications and drawings design and can also participate in the design and development of products as well as provide OEM and ODM, have an R D facility covers more than 500 square meters, with professional R D personnel and equipment, that can collaborate in tungsten copper alloy and testing of products and offer a range of processing equipment to satisfy diverse customer requirements.

company put in place the quality control process which rigorous ensure that products to standards. We select high-quality suppliers ensure traceability quality control of supply chain runs from raw materials through the final products. have obtained ISO9001 as well as SGS certifications, which in accordance with tungsten copper alloy and industry standards. create quality management strategies as well as conduct quality inspections and tests, as well as record the production process in accordance with rare metal and non-ferrous industrial specifications.