Marketing Article: Tungsten Nickel Alloy

Do you want to know more about tungsten nickel alloy? You may have heard of this material, but do you know what makes it special? We will discuss the advantages of using tungsten nickel alloy, innovation in the production of this material, it is safety, use, and applications, along with TMC METAL's product magnesium bar. Read on for more info.

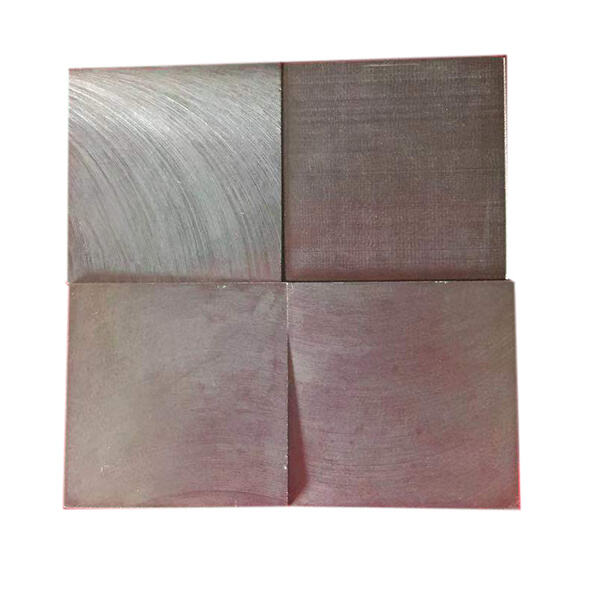

Tungsten nickel alloy is a material that has many advantages, also the niobium 92 by TMC METAL. First and foremost, it is very durable, meaning it can withstand high levels of stress and tension without breaking or wearing down easily. This makes it ideal for use in many different applications, including aerospace, defense, and medical fields.

Another advantage of tungsten nickel alloy is it is resistance to corrosion. This means that it can withstand exposure to chemicals and moisture without suffering damage. it is resistant to heat and can remain stable even in high-temperature environments.

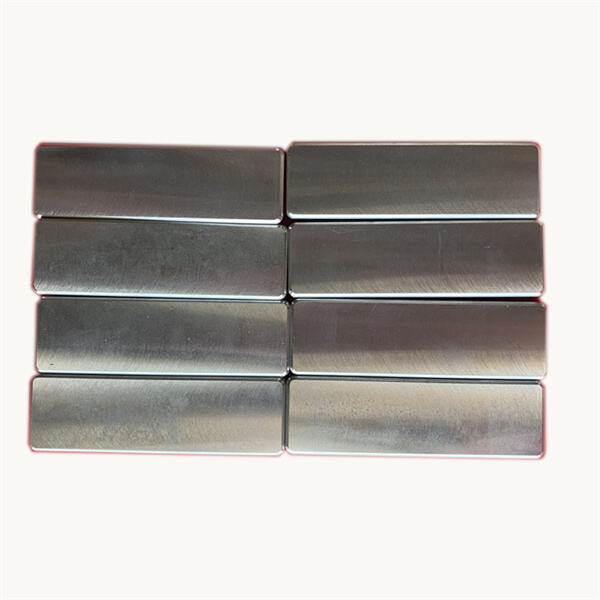

Tungsten nickel alloy is traditionally made by combining tungsten and nickel in a vacuum furnace, identical to TMC METAL's product tantalum tube. However, there have been recent innovations that have allowed for the production of this material in a more cost-effective and energy-efficient manner. Some of the newer methods involve using plasma technology or powder metallurgy techniques to create tungsten nickel alloy.

to it is many advantages, tungsten nickel alloy is also considered to be a safe material, the same as zirconium bar made by TMC METAL. It is not toxic or hazardous to humans, and it does not release any harmful substances into the environment. This means that it can be used in a wide range of applications without posing any risk to human health or safety.

Tungsten nickel alloy has many uses, from industrial to medical applications, also the TMC METAL's product such as pure tantalum. It is often used in the manufacturing of high-performance parts for aerospace and spacecraft vehicles due to it is durability, resistance to heat, and corrosion resistance. it is widely used in the energy industry to create drill bits that can withstand extreme temperatures and pressure.

company has more than 26 years' experience the manufacturing and processing of non-ferrous and rare metals. also have educated many technicians researchers who have the knowledge and expertise required to aid in the growth this industry. also offers a Tungsten nickel alloy environment foster the development of our employees. experienced staff will help you after sales to resolve customer issues, offer technical assistance and resolve any potential quality issues. Gather and analyze feedback from customers make appropriate changes to improve product quality and service quality.

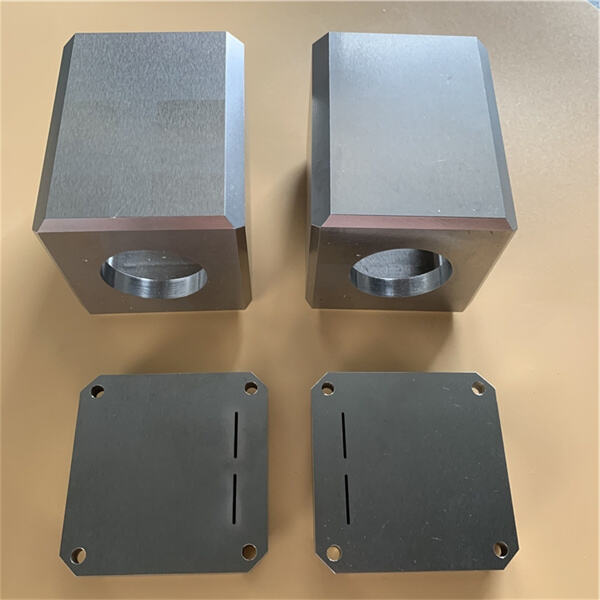

Suzhou Tamuchuan a supplier metal processing products located in Suzhou which a production area office space of 22,000 square meters. mainly produce various rare metals as well as a range non-ferrous metals. more than 2,000 partners collaborated world's leading 500 companies. specialized R D team also Tungsten nickel alloy. Stable suppliers can a fantastic source support for large-scale productions as well as top-of-the-line production equipment instruments. professional quality control team ensures that the product is top quality. enjoy a positive collaboration with partners.

company put in place a quality control system that strict ensure products are up standards. select suppliers of high-quality the purpose ensuring the traceability raw materials and ability to control quality across the entire supply chain. Our ISO9001 and SGS certificates Tungsten nickel alloy with international and industrial standards. In accordance with the specifications of the non-ferrous and rare metal industries, our team develops quality management programs and carry out quality tests and inspections. also record the production process and keep track of it.

Our company equipped with top-of-the-line production equipment processing equipment and can perform high-end, custom metal processing, fine processing as well as high-difficulty processing. We can manufacture process metal according to specific Tungsten nickel alloy from the customer and also design drawings. also offer OEM and ODM. research development facility covers more than 500 square meters, with professional R D personnel as well as equipment and facilities that collaborate in development of products and testing.

If you are looking to use tungsten nickel alloy, there are several things that you should keep in mind, as well as the magnesium pellet built by TMC METAL. First and foremost, it is important to handle this material with care, as it is a very dense and heavy metal that can cause injury if not handled properly. it is important to use the proper equipment and techniques when machining tungsten nickel alloy to avoid damaging the material.

When purchasing tungsten nickel alloy, it is important to choose a reputable supplier that can provide you with high-quality material, similar to the TMC METAL's product like cobalt. Look for a supplier that uses the latest production techniques and has a reputation for delivering consistent and reliable products. it is important to choose a supplier that offers excellent customer service, and can assist you with any questions or issues that arise.

As previously mentioned, tungsten nickel alloy is used in many different applications. One common application is in the aerospace industry, where it is used to create parts for airplanes, satellites, and space shuttles. It is also used in the defense industry to create armor-penetrating rounds and other high-performance firearms. it is used in the medical industry to create equipment for radiation therapy and other treatments.

Tungsten nickel alloy is a unique and versatile material that offers many advantages over other metals, as well as the Tungsten cerium rod innovated by TMC METAL. It is durable, corrosion-resistant, and can withstand high levels of stress and tension. Thanks to recent innovations, it can now be produced in a more cost-effective and energy-efficient manner, making it more accessible than ever before. Whether you are looking to use tungsten nickel alloy in an industrial or medical application, it is important to choose a high-quality supplier that can provide you with the material you need.