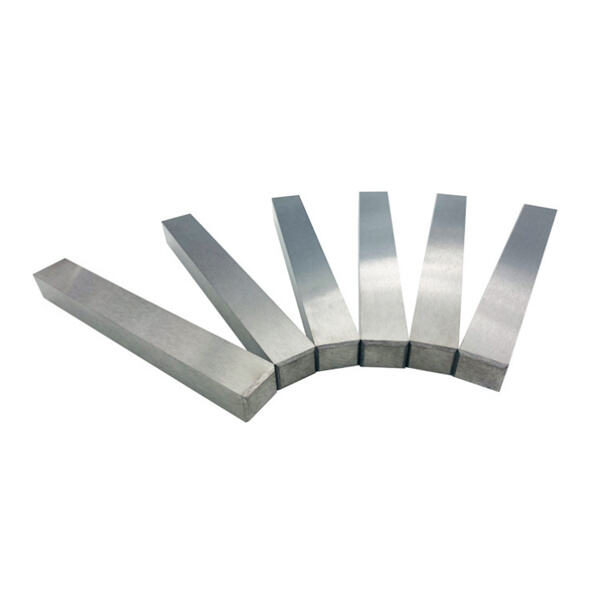

Tungsten nickel alloy is a highly durable and sturdy material that is in demand across multiple industries. It’s special because it can withstand high temperatures and stress. That makes it great for parts in airplanes, cars, medical devices and advanced engineering tools, among other things. Now let’s take a look at why Tungsten Nickel Alloy is significant.

Tungsten nickel alloy is composed of two metals: tungsten and nickel. Both are superstrong, super durable. Together, they produce a material that’s stronger still. This is what makes tungsten nickel alloy ideal for parts that are required to have a long life.

One of the greatest things about tungsten nickel alloy is how it withstands corrosion. This material can be used in many different environments because of that. From chemicals to water to intense temperatures, tungsten nickel alloy stays strong.

Parts that will stand up to rough conditions are crucial to industries like aerospace and automotive. She said, including high temperatures and a considerable amount of stress. These industries are very suitable for tungsten nickel alloy, because these problems can be easily solved by it.

In the automotive sector, the material is applied to auto and truck parts. It helps to manufacture engine parts and suspension systems, and plays a central part in keeping cars safe and operating smoothly. This makes it an excellent choice for these high-performance applications.

Wolfram nickel alloy is additionally ideal for high technology engineering. This involves machinery, tools and equipment that operate in harsh environments. No way is it crude, however- its reliability and strength are the reason why it is the only material you should use for these tasks.

One of the reasons why tungsten nickel alloy from TMC METAL is so popular has to do with its corrosion resistance. It is ideal for all around use with its scrim backing and wood filled core. Resistant to water and chemicals and tolerant of high- and low-temperature applications, this alloy is the only beaker you need.

facility equipped with latest production processing equipment. can also perform advanced metal processing that customized delicate processing and hard processing. We are able manufacture process metal parts designs and specifications the customer. also provide OEM and ODM. Our research development center covers larger than 500 square meters and is equipped with expert R D staff, equipment and facilities that allow for tungsten nickel alloy in developing and testing products.

Suzhou Tamuchuan, processing product tungsten nickel alloy in Suzhou manufacturing office area of 2,000 square meters, located there. primary products include rare metals, non-ferrous metals and various other types of metals. We have more than 2,000 partners have cooperation with world's top 500 companies. A specialized R D team available. Stable suppliers can be a fantastic support for large-scale productions, as well as top-of-the-line production equipment and instruments. We have highly skilled quality inspection team strictly control product quality. We have a good collaboration with our partners.

company set up and implemented rigorous quality control system ensure that products meet predetermined standards specifications. choose high-quality suppliers for the purpose of ensuring traceability raw materials, as well as tungsten nickel alloy controllability throughout supply chain. ISO9001 and SGS certificates are in compliance with industry and international standards. In accordance with specifications of the non-ferrous and rare metal industries, formulate quality management programs and carry out quality tests as well inspections. We also record and monitor our production processes.

company has more than 26 years' experience in processing and production rare metals non-ferrous alloys. have also educated many personnel in R D and technical with the professional knowledge needed help in the development this industry. also provide a platform employee development. have experienced tungsten nickel alloy who can provide you with after-sales service assistance to resolve customer issues, provide technical assistance and resolve potential quality issues. Make the necessary changes improve the quality of your products as well as customer service, by gathering and analyzing feedback from clients.