Molybdenum Alloys: The Superhero of Metals.

Are you looking for a tough material and durable? Look no further than molybdenum alloys. Molybdenum alloys are made from an unique combination of metals, and they have a variety of advantages over other materials. These TMC METAL molybdenum alloys are gaining popularity in modern industries for their unique properties, which make them ideal for use in a variety of products.

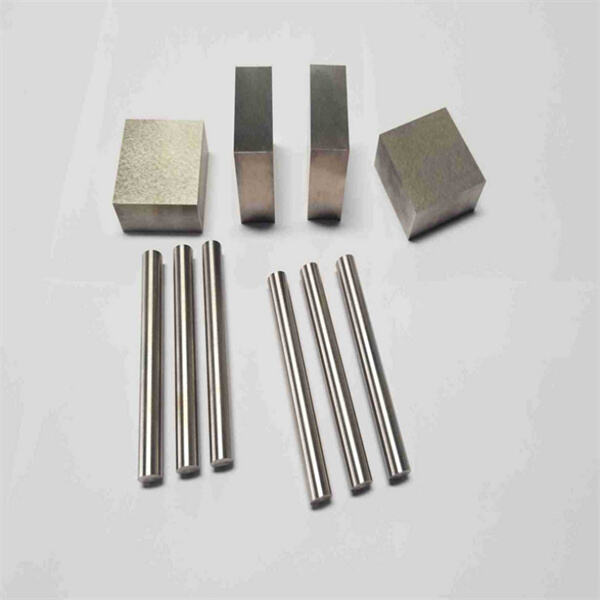

Molybdenum alloys are known for their high melting point, which makes them resistant to extreme temperatures and radiation. They are also hard and durable, which means they can last a long time without wearing down. Additionally, TMC METAL molybdenum and tungsten are corrosion-resistant, so they will not rust or corrode over time. All of these properties make molybdenum alloys the perfect choice for a variety of applications.

In recent years, there has been a lot of innovation in the field of molybdenum alloys. Many scientists are experimenting with different combinations of metals to create alloys that are even stronger and more durable than traditional molybdenum alloys. This has led to an increase in the use of these TMC METAL molybdenum tungsten in a variety of industries, including aerospace, automotive, and electronics.

One of the best things about molybdenum alloys is that they are safe to use. Unlike other materials that may be harmful to humans or the environment, TMC METAL tungsten molybdenum alloy are non-toxic and environmentally friendly. This means that they are a great choice for used products in or near people.

Molybdenum alloys are easy to use and are compatible with a variety of manufacturing methods. TMC METAL molybdenum can be melted down and formed into different shapes, making them ideal for use in a variety of products. Some common uses for molybdenum alloys include in the production of aircraft parts, as electrical contacts, and in the production of high-performance electrical components.

Suzhou Tamuchuan, processing company supplies products located Suzhou with a production facility office space of 2,000 square meters which located in city. main products offer rare metals, ferrous metals as well various other metals. More than 2,000 {{keywords}}' partners cooperate with. experienced R D group available. stable suppliers can assist with large-scale production, high-end production equipment tools. professional quality control team ensures that the product of the highest quality. have good partnership with our suppliers.

company has more than 26 years of experience manufacturing and processing rare metals and non-ferrous alloys. We have educated an extensive number of technical and R D staff with the professional Molybdenum alloys needed help in development of this industry. also offer a supportive environment for development employees. team of experts can offer support following sales resolve customer issues, offer technical assistance and resolve potential quality issues. Implement the appropriate measures enhance the quality the product customer service by collecting and analyzing feedback from clients.

company has implemented internal quality control system that stringent to ensure that products are to standards. choose high-quality suppliers ensure the quality of raw materials as well as control of quality across entire supply chain. have been awarded ISO9001 SGS Molybdenum alloys that conform industry and international standards. design quality management programs to conduct quality inspections and tests, as well as record the production process conforming to rare metal and non-ferrous metal industry specifications.

Our company equipped with top-of-the-line production equipment processing equipment and can perform high-end, custom metal processing, fine processing as well as high-difficulty processing. We can manufacture process metal according to specific Molybdenum alloys from the customer and also design drawings. also offer OEM and ODM. research development facility covers more than 500 square meters, with professional R D personnel as well as equipment and facilities that collaborate in development of products and testing.

When it comes to service and quality, molybdenum alloys have a lot to offer. The manufacturing process for these TMC METAL Tungsten and molybdenum processing parts is closely monitored to ensure that they are of high quality and meet industry standards. Additionally, many companies that specialize in molybdenum alloys offer excellent customer service to help you find the right product for your needs.

Molybdenum alloys are used in a wide variety of applications, from the production of aircraft parts to the creation of high-performance electrical components. One of the most common uses for molybdenum alloys is in the aerospace industry, where they are used to make parts that need to withstand extreme temperatures and radiation. Additionally, molybdenum alloys are commonly used in the automotive and electronics industries.

molybdenum alloys are a wonderful choice for anyone looking for a durable, long-lasting material. These alloys have a variety of advantages, including their high melting point, hardiness, and corrosion resistance. TMC METAL molybdenum sheet are also safe to use and environmentally friendly. Moreover, they have been the subject of lots of innovation in recent years, which means that even stronger and more durable alloys will be available soon. Overall, molybdenum alloys are a fantastic choice for anyone who needs a tough, durable, and reliable material.