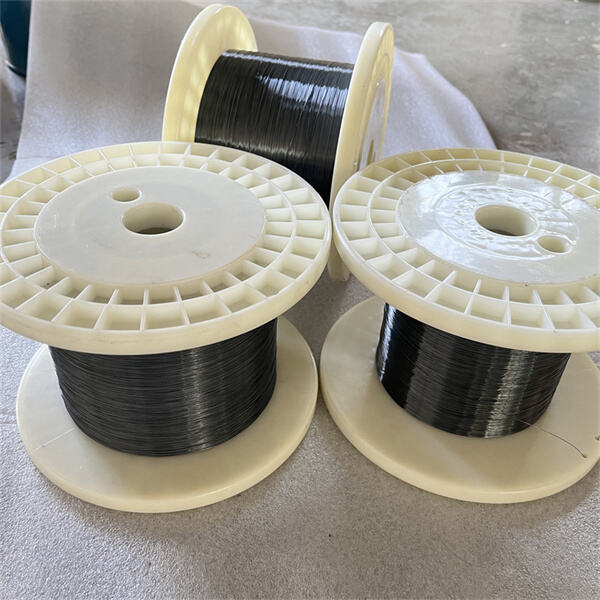

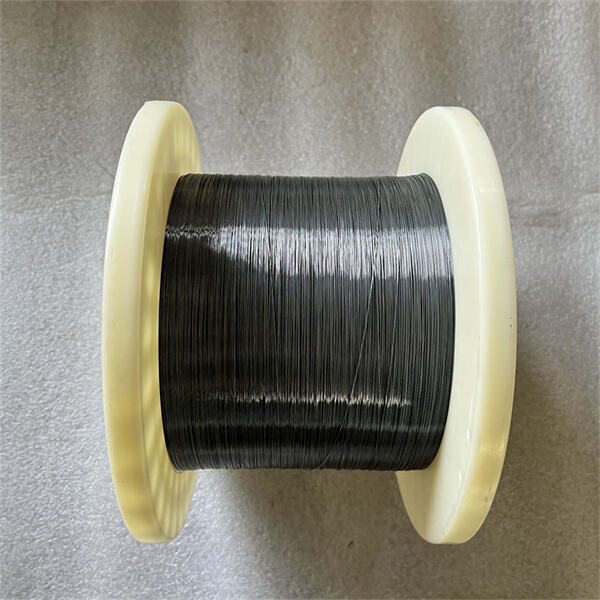

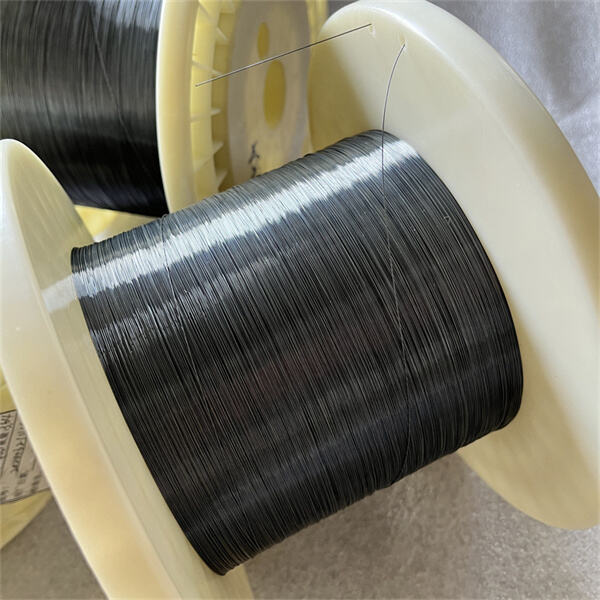

Niobium titanium wire is a very special kind of metal that can perform many seemingly magical feats. This special wire that’s made by TMC METAL has a variety of uses. To find out this and more about how niobium titanium wire can be beneficial to us, we continue our discussion.

Orthodontic braces enable anyone to have straight teeth and an attractive smile. Niobium titanium wire is also good for braces because the dentist can easily bend or adjust it. That is, the band and braces can be adjusted to encourage teeth to move to the right place. The wire is also extremely strong, keeping the braces in place.

Aerospace engineering is the science of how to design and build aircraft, among other things. Niobium titanium wire is lightweight and strong, and is utilized in this field. This kind of special wire is resistant to high temperatures and can take a lot of force, which makes it ideal for use in airplanes and rockets. The niobium titanium wire for TMC Metal is of high quality and can be used in aerospace engineering.

Materials and methods: Niobium titanium wire is playing a variety of roles in medical and health work. And, this special wire can be employed to produce surgical equipment which are robust and long-lasting. It is also utilized in medical implants like pacemakers, as it is safe for the body and does not cause any damage. TMC METAL offer the best quality niobium titanium wire for developing medical sector.

Niobium titanium wire holds up in tough, wear-and-tear heavy industries. This special wire is used in machines and instruments that must be strong and dependable. TMC METALメーカー/factory/niobium titanium wire for industrial uses Whether it’s in a factory or on a construction site, you’ll find TMC METAL’s niobium titanium wire being used for industrial purposes.

Niobium titanium wire is also significant in technology. It is found in electronic equipment like phones and computers because it is very good at conducting electricity. This special wire is also very good at conducting heat and can withstand high temperatures, an important quality when it comes to electronic devices that can get hot in use. TMC METAL supplies high-quality niobium titanium wire used in electronics.

company established the quality control process is strict to ensure products up the standards. We choose high-quality suppliers ensure traceability raw materials, well as control quality across the entire niobium titanium wire chain. ISO9001 and SGS certifications are in line with international and industrial standards. meet specifications of rare and non-ferrous metal industries, develop quality management strategies and conduct quality checks as well as inspections. We also keep records and monitor our manufacturing processes.

company has over 26 years' experience rare and non-ferrous metal processing as well as production. have cultivated an extensive number of technicians and R D professionals who have professional expertise contribute to the niobium titanium wire of the industry. also provide environment to foster development our employees. have team professionals offer you after-sales service as well as support for customer issues, provide technical assistance and help solve quality problems. Analyze and collect feedback from customers take appropriate measures improve the quality of products and service quality.

Suzhou Tamuchuan is industrial metal processing company located in Suzhou has a niobium titanium wire space and office area 22,000 square meters. We mainly produce various rare metals and a variety of non-ferrous metals. have over 2,000 suppliers and have cooperation with the world's top 500 companies. also have an experienced R D team. Stable suppliers provide great source of support for large-scale productions addition to top-of-the-line production equipment and instruments. have a highly skilled quality inspection team that able to control product quality. have developed a strong cooperative relationship with our partners.

company uses top-quality niobium titanium wire equipment processing equipment and able to perform high-end custom metal processing, high-end processing, and complex processing. can produce and process metal parts according customer specifications and design drawings. also provide OEM and ODM. Our research development center covers more than 500 square meters and is equipped with expert R D staff as well as equipment and facilities that can work together in the development of products and testing.