Advantages of Tungsten Plate

Tungsten plate is a metal high-density has some unique advantages over other types of metals of TMC METAL. For starters, tungsten has a melting high, making it perfect for use in high-temperature settings such as furnace insulation, electrical contacts, and welding applications.

Additionally, tungsten plate has wear excellent corrosion resistance, making it ideal for use in harsh environments. This material is also incredibly strong and durable, making it well-suited for more heavy-duty applications where longevity and strength are essential.

In recent years, tungsten plate has undergone innovation significant make it safer for use in various applications. Manufacturers have developed new alloys and coatings that enhance the material's already impressive hardness and wear resistance while also safety improving.

For example, tungsten carbide is a coating common to improve the wear resistance of tungsten plate or the TMC METAL tungsten carbide metal. This coating can reduce the risk significantly of dangerous debris from breaking off the metal during use, making it much safer for workers in industries such as mining and construction.

Tungsten plate has a variety wide of in many different industries. For example, it is commonly used in aerospace and aviation, where it is used for components such as electrical contacts and engine parts because of its resistance high-temperature and.

Similarly, tungsten plate is also commonly used in electrical applications, such as in filament wires of the TMC METAL and contacts that are electrical. It also has applications in the industry medical where it is used for X-ray tubes and radiation shielding due to its high density.

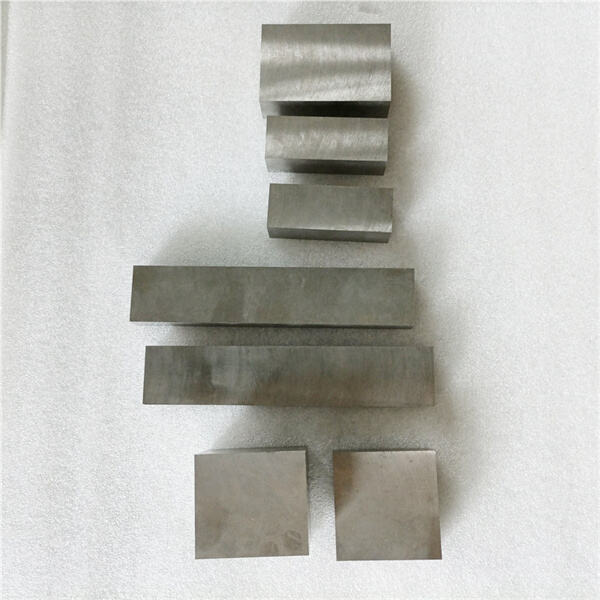

Tungsten plate is a material versatile is relatively easy to work with, making it perfect for use in many different applications. The most way common use tungsten plate similar to TMC METAL tungsten rod is to machine it to the desired shape and size, which can then be welded or brazed into place.

Alternatively, it is possible to use tungsten plate in sheet form, which can be easily cut to size and used for a variety of applications. It is essential to use appropriate safety precautions when working with tungsten plate, such as for example wearing gloves, eye protection, and performing any cutting or machining in a area well-ventilated.

When considering a material like tungsten plate, it is essential to choose a supplier with a reputation for excellent quality and service. A good supplier like the TMC METAL tungsten pellet will be able to provide you with tungsten plate that meets your specific requirements, whether that means sourcing a particular size or shape or providing advice on the alloy best or coating for your use case.

A quality supplier will be able to provide you with tungsten plate that meets strict quality standards, ensuring the material's durability, wear resistance, and safety at the same time.

company set up and implemented rigorous quality control system ensure that products meet predetermined standards specifications. choose high-quality suppliers for the purpose of ensuring traceability raw materials, as well as Tungsten plate controllability throughout supply chain. ISO9001 and SGS certificates are in compliance with industry and international standards. In accordance with specifications of the non-ferrous and rare metal industries, formulate quality management programs and carry out quality tests as well inspections. We also record and monitor our production processes.

company has more than 26 years of experience manufacturing and processing rare metals and non-ferrous alloys. We have educated an extensive number of technical and R D staff with the professional Tungsten plate needed help in development of this industry. also offer a supportive environment for development employees. team of experts can offer support following sales resolve customer issues, offer technical assistance and resolve potential quality issues. Implement the appropriate measures enhance the quality the product customer service by collecting and analyzing feedback from clients.

Suzhou Tamuchuan a metal processing product supplier located Suzhou with a production office space of 2,000 square meters which is located in the city. Our main products are rare metals, ferrous metals, various other metals. More than 2,000 companies and partners cooperate with. We also have an Tungsten plate R D team. The stable suppliers can assist with production on a large scale, with high-end equipment and instruments. We have a professional quality inspection team that able ensure the quality of our products. We have established a good collaboration with partners.

company equipped with top-of-the-line production equipment processing equipment can undertake high-end customized metal processing, fine process, and high-difficulty processing. We able produce process metal parts designs and specifications of customer. also Tungsten plate OEM and ODM. Our research and development center larger than 500 square meters that is staffed professional R D personnel, equipment and facilities can work together in the development of products and testing.

There are many applications that are different tungsten plate or the TMC METAL tungsten tube, ranging from heavy industrial settings to high-tech applications like medical and aerospace. Some uses that are common tungsten plate include:

- Electrical contacts and circuit breakers

- X-ray tubes and radiation shielding

- Furnace components and insulation

- Filament wires and welding electrodes

- High-temperature tools and dies